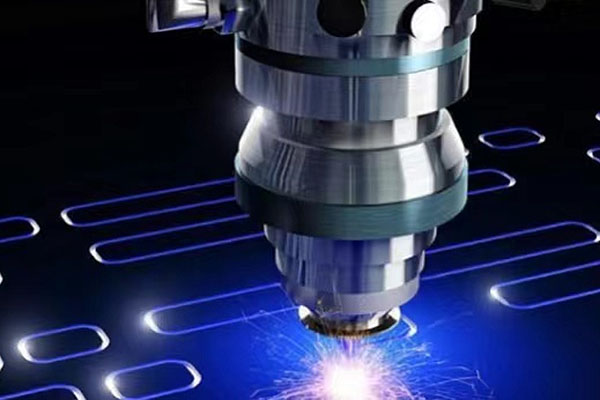

Fasahar alamar Laser shine ɗayan manyan wuraren aikace-aikacen sarrafa Laser. Tare da m ci gaban da sakandare masana'antu, Laser ana amfani da ko'ina a daban-daban aiki da kuma masana'antu masana'antu, kamar Laser alama, Laser yankan, Laser waldi, Laser hakowa, Laser proofing, Laser ji, Laser engraving, da dai sauransu Duk da yake accelerating samar da Enterprises, shi ma accelerated da m ci gaban da Laser masana'antu.

Laser na ultraviolet yana da tsayin tsayin 355nm, wanda ke da fa'idodin gajeren zango, gajeriyar bugun jini, ingantaccen ingancin katako, daidaitaccen ƙarfi, da ƙarfin kololuwa; sabili da haka, yana da na halitta abũbuwan amfãni a Laser marking. Ba shine tushen laser da aka fi amfani dashi don sarrafa kayan aiki kamar infrared lasers (tsawon tsayin μm 1.06). Duk da haka, robobi da wasu polymers na musamman, irin su polyimide, waɗanda ake amfani da su a matsayin kayan aiki don sassauƙan allon allo, ba za a iya sarrafa su ta hanyar jiyya ta infrared ko jiyya na "thermal".

Saboda haka, idan aka kwatanta da koren haske da infrared, ultraviolet lasers suna da ƙananan tasirin zafi. Tare da gajarta na Laser raƙuman ruwa, daban-daban kayan da mafi girma sha rates, har ma kai tsaye canza kwayoyin sarkar tsarin. Lokacin sarrafa kayan da ke kula da tasirin thermal, Laser na UV suna da fa'ida a bayyane.

Grid Laser TR-A-UV03 Laser mai sanyaya ruwa na iya samar da Laser ultraviolet na 355nm tare da matsakaicin ƙarfin fitarwa na 1-5W a ƙimar maimaitawar 30Khz. Wurin Laser ƙarami ne kuma faɗin bugun bugun yana kunkuntar. Yana iya sarrafa sassa masu kyau, ko da a ƙananan bugun jini. A ƙarƙashin matakin makamashi, ana iya samun yawan ƙarfin kuzari, kuma ana iya aiwatar da sarrafa kayan aiki yadda ya kamata, don haka za'a iya samun ingantaccen tasirin alama.

The aiki manufa na Laser alama ne don amfani da high-makamashi-yawa Laser to partially irradiate da workpiece to vaporize da surface abu ko sha wani photochemical dauki na launi canji, game da shi barin dindindin alama. Kamar maɓallan madannai! Yawancin maɓallan madannai a kasuwa yanzu suna amfani da fasahar inkjet. Da alama haruffan da ke kan kowane maɓalli a bayyane suke kuma ƙirar tana da kyau, amma bayan ƴan watanni da aka yi amfani da su, an kiyasta cewa kowa zai ga cewa haruffan da ke kan madannai sun fara yin duhu. Abokan da aka sani, an kiyasta cewa za su iya yin aiki ta hanyar ji, amma ga yawancin mutane, maɓalli mai maɓalli na iya haifar da rudani.

(Alamar Maɓalli)

Laser 355nm ultraviolet Laser na Gelei Laser nasa ne na sarrafa "haske mai sanyi". Ana iya raba shugaban Laser na ultraviolet mai sanyaya ruwa da akwatin samar da wutar lantarki. Shugaban laser karami ne kuma mai sauƙin haɗawa. . Yin alama akan kayan filastik, tare da ci gaba ba tare da tuntuɓar sadarwa ba, baya haifar da haɓakar injiniya ko damuwa na inji, don haka ba zai lalata abubuwan da aka sarrafa ba, kuma ba zai haifar da nakasu ba, rawaya, ƙonawa, da dai sauransu; don haka, yana iya zama Kammala wasu sana'o'in zamani waɗanda ba za a iya samun su ta hanyoyin al'ada ba.

(Alamar allo)

Ta hanyar sarrafa kwamfuta mai nisa, tana da halaye na musamman na aikace-aikace a fagen sarrafa kayan masarufi, yana iya rage tasirin zafi a saman kayan daban-daban, kuma yana haɓaka daidaiton aiki sosai. Alamar Laser ta ultraviolet na iya buga haruffa daban-daban, alamomi da alamu, da sauransu, kuma girman halayen na iya zuwa daga milimita zuwa microns, wanda kuma yana da mahimmanci na musamman don hana jabun samfur.

Yayin da masana'antar lantarki ke haɓaka cikin sauri, fasahar aiwatar da masana'antu da OEM kuma koyaushe suna haɓakawa. Hanyoyin sarrafa kayan gargajiya ba za su iya biyan buƙatun kasuwa na mutane ba. Ultraviolet Laser daidaici Laser yana da ƙananan tabo, kunkuntar bugun jini nisa, karamin zafi tasiri, High dace, makamashi kiyayewa da muhalli kariya, machining machining ba tare da inji danniya da kuma sauran abũbuwan amfãni ne manufa inganta ga gargajiya matakai.

Lokacin aikawa: Nuwamba-17-2022